EMI Shielding Products

- Custom Gasket Fabrication

- Connector Gaskets

- Bonded O Ring

- Custom Gaskets

- Conduct-O-Knit Knitted Wire Mesh

- Conduct-O-Seal Combo Gasket

- Conduct-O-Elastomer

- Conduct-O-Seal Oriented Wire in Silicone Gasket Material

- Conduct-O-Mesh Tape

- Conduct-O-Foam

- Conduct-O-Bond

- Optical Filters For Electronic Displays

- Shielded Vent Panels

- 300 Series

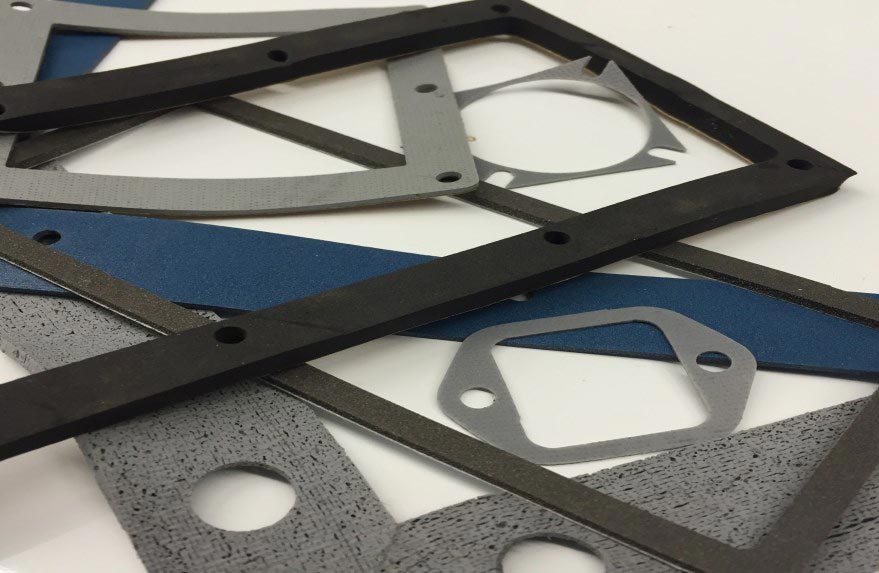

Different Types of Gaskets

Gaskets are components of industrial applications that help to seal joints in order to prevent leaks, limit vibration, and enhance mounting. There are many different types of gaskets and each are classified by material, function, and application. Typically, a gasket is manufactured with a soft, flexible material and sits between two separate surfaces. This article will help identify different types gaskets by there make up, purpose, and uses.

Gaskets classified by types of material:

Each gasket adopts the characteristics of the materials that it is manufactured with. Different materials are used in order to adhere to the resistance effects of certain chemicals, extreme temperatures, and different types of pressures.

Rubber Gaskets:

Rubber is an excellent soft gasket material that is used for pipe gaskets, heat exchangers, and man ways. These gaskets are used across a number of industries.

Cork Gaskets:

When combined with rubber, cork gaskets offer high flexibility and compression. These gaskets are commonly used in industries that use oil, fuel, and solvents.

Different uses for Gaskets:

In addition to composition, Gaskets are commonly grouped by their industrial application and purpose; sealing, anti vibration, and mounting are the three most common uses.

Sealing:

Sealing is the most important function of a gasket. The primary function of many gaskets is to prevent leaks in industrial system. Most sealing gaskets are fashioned from rubber, as rubber is an excellent way to block water.

Environmental Seals:

Gaskets that seal against dust, dirt, and other miniature particles are known as environmental sealing gaskets. These seals are predominantly used in enclosures that control equipment that is vital to the larger industrial operation.

Anti Vibration:

All machines produce vibration and frequency. Anti vibration pads are gaskets that disrupt vibration and frequencies. By muffling vibration, the amount of energy that is wasted is limited. Damage from vibration is also stifled with an anti vibration gasket.

Gaskets that are used in Piping:

Flange Gaskets:

Flange gaskets are made from a conglomeration of materials such as rubber, non-asbestos, and graphite. Gaskets can be designed in two different ways: full faced or inner bolt. Full faced gaskets cover the whole flanged and can be easily spotted because the holes for the bolts are cut directly into the material of the gasket.

Inner Bolt:

Inner bolt gaskets are commonly referred to as ring type or raise face. A circle of bolts, which secure the joint and form a ring, surrounds these gaskets.

Related Reading

- EMI Gaskets and Shielding for the Modern Automotive Industry

- RFI and EMI: Frequent Questions

- Difference between EMI and EMC

- RFI Shielding in the Medical Field

- Common Shielding Metals