EMI Shielding Products

- Custom Gasket Fabrication

- Connector Gaskets

- Bonded O Ring

- Custom Gaskets

- Conduct-O-Knit Knitted Wire Mesh

- Conduct-O-Seal Combo Gasket

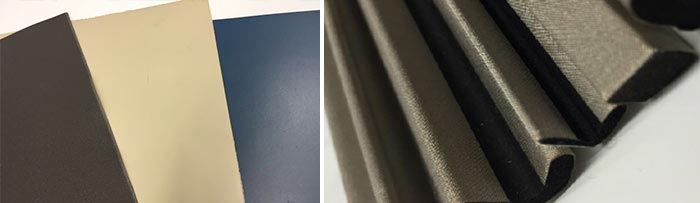

- Conduct-O-Elastomer

- Conduct-O-Seal Oriented Wire in Silicone Gasket Material

- Conduct-O-Mesh Tape

- Conduct-O-Foam

- Conduct-O-Bond

- Optical Filters For Electronic Displays

- Shielded Vent Panels

- ESC Board Level Shielding

- 300 Series

EMI use of Gaskets in Military

The U.S military is a huge global entity, and shielding electronic equipment is crucial for today’s large military forces. The majority of operations are highly dependent on electronic communication devices. Without the assistance of these tools, missions would be a less organized and highly dangerous. To protect these vital pieces of equipment the army uses electronics that are protected by shielding gaskets.

Electronic shielding gaskets protect equipment from electromagnetic pules and electronic interference. The gaskets insure that instruments are able to record and send out data, no matter what. EMPs are instruments of war that aim to disturb communication systems. When communications in the military go down, missions and operations go into complete disarray. The key to a good military is establishing concrete communication lines so troops can have a clear dialogue with each other. In a fast pace war environment, variables change all the time, and troops need to be made aware of these happenings instantaneously.

Soldiers endanger their lives on a daily basis, and the equipment that they use is responsible for keeping them alive. The causes for EMI are numerous, and can be caused by a myriad of agents: radio transitions, electric motors, computers, and power lines. Enemy troops often use electronic jamming device to disrupt communication. The gaskets that are built to protect these devices need to be durable and effective. Designers of EMI gaskets use select materials that have the certain properties capable of war like conditions. Many of these gaskets are designed with inert rubber silicon that has many advantages. This material has a wide resistance to temperatures, UV light rays, and is waterproof. Not only do these gaskets provide EMI shielding, they also ensure protection from environmental elements. Soldiers can often be stationed off based in a variety of different locations. It can be wet, muddy, extremely hot or cold, and a solider will still have to rely on their equipment.

EMI RFI Shielding

Manufacturers that design equipment for the military have to follow strict building codes. Military personal rely on this equipment to save their life, so it cannot fail, under any circumstances. Designers and buyers are both responsible to understand the wide applications that military equipment are used for and must build products that are capable of appeasing military regulations and standards. If you are interested in designing or purchasing EMI RFI shielding gasket, make sure to contact a professional in the field.

Related Reading- Mounting a Shielding GasketShielding gaskets are vital products for many different industries that deal with EMI or RFI. The different applications and industries throughout the world rely on the products being made strong, durable, and able to resist EMI.

- Understanding Oriented Wire Shielding and how it Works

- The Science of Shielding

- Shielding Gaskets and Corrosion

- Selection of Seal Cross Section

- Integrated Circuits Have Problems with EMI

- RFI and EMI: Frequent Questions

- Difference between EMI and EMC

- RFI Shielding in the Medical Field

- Common Shielding Metals