EMI Shielding Products

- Custom Gasket Fabrication

- Connector Gaskets

- Bonded O Ring

- Custom Gaskets

- Conduct-O-Knit Knitted Wire Mesh

- Conduct-O-Seal Combo Gasket

- Conduct-O-Elastomer

- Conduct-O-Seal Oriented Wire in Silicone Gasket Material

- Conduct-O-Mesh Tape

- Conduct-O-Foam

- Conduct-O-Bond

- Optical Filters For Electronic Displays

- Shielded Vent Panels

- 300 Series

EMI Shield Manufacturing Processes

Technology is all around us, and with each day it becomes more and more prevalent. It is hard to go a whole day without using or seeing some sort of electrical device. These devices produce electromagnetic radiation, which can have a significant adverse effect on surrounding electronic devices. For instance, a phone that does not have proper shielding will leak EMI and disrupt other cellular devices in the area.

Luckily, EMI shielding will protect devices from bleeding EMI in the environment. Considering that so many different devices require shielding, the construction process of shields is extensive to accommodate the unique needs of companies building electronic devices. For instance, there are four ways to construct both EMI and RFI shielding. The fabrication process of shield matters for applications (especially EMI silicones).

- Die Cutting- the extremely precise gaskets best support nested parts, as well as slots with fasteners. Die cutting also can produce pressure sensitive adhesive backing and kiss-cutting.

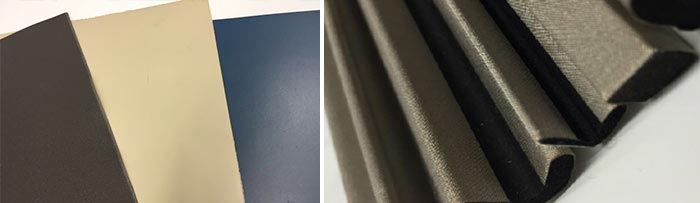

- Extruded EMI Shielding Gaskets- This method of construction is best when working with groove or flange operations. Extrusion can create unusual shapes. Thin layers of precious shielding metals can be attached to the outside layer of conductive silicone.

- Molded EMI Shields- this method of construction limits waste because the molding fully conforms to all design requirements. Cost is reduced by getting rid of the center drop waste.

- Form-in-Place process- final products can achieve up to a 30% lessened compression force, as well as fewer materials consumed, and an increase in PCB area. All of this is accomplished while still maintaining high shielding properties.

EMI RFI Shielding

It is not easy to determine the best creation method for RFI and EMI shielding. At Eastcoast Shielding, we have the answers to all your shielding questions. EMI/RFI shielding can be custom made to fit preexisting models, we can help you through custom shield designs.

Related Reading- Three Methods for Producing EMI Shielding GasketsEMI shielding gaskets are needed to boost the performance of electronic applications and equipment.

- Does EMI Matter?

- EMI Regulations