EMI Shielding Products

- Custom Gasket Fabrication

- Connector Gaskets

- Bonded O Ring

- Custom Gaskets

- Conduct-O-Knit Knitted Wire Mesh

- Conduct-O-Seal Combo Gasket

- Conduct-O-Elastomer

- Conduct-O-Seal Oriented Wire in Silicone Gasket Material

- Conduct-O-Mesh Tape

- Conduct-O-Foam

- Conduct-O-Bond

- Optical Filters For Electronic Displays

- Shielded Vent Panels

- ESC Board Level Shielding

- 300 Series

EAST COAST SHIELDING

Bonded O-Rings

East Coast Shielding is one of the nation’s premier fabricators of O-rings. We offer O-rings in a wide range of material types. In-cluding extruded & vulcanized types of rubber, conductive materials and more. We have O-ring stock available in standard inch sizes, as well as metric. We can also create custom O-rings to meet your specifications. Need an O-ring designed? We can do that too! We are proud to supply O-rings across the country, and around the world, to companies in over a dozen different industries.

SPLICED and VULCANIZED O-RINGS

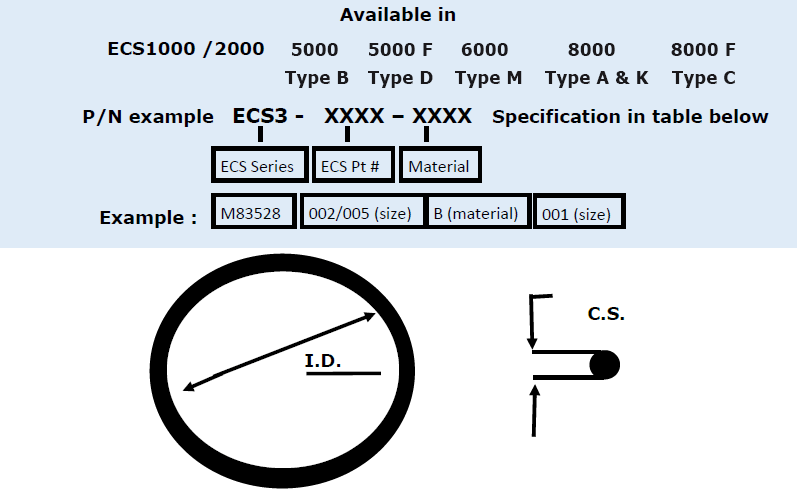

ECS3 Series & ECS300 Series Capabilities

East Coast Shielding provides spliced or vulcanized O-rings made from conductive & non-conductive silicone that can be used in environmental sealing and other semiconductor processing applications. Extruded cord stock is available in many standard cross-sections. Spliced or vulcanized O-rings are made from an extruded cord and then vulcanized to form the O-ring size (ID) required. Spliced O-rings are a low cost, effective solution when standard O-rings cannot be used. East Coast Shielding provides spliced O-rings with ID’s that range from 1” up. Splices at the joints are almost seamless.

Splicing method created by East Coast Shielding enables a quick production of O-rings that conform to most industry specifica-tions or to your custom requirements. This technology reduces the manufacturing time for spliced O-rings as well as the cost hurdles associated with custom O-rings. Whether your intended use is prototyping or large-scale commercialization, spliced O-rings deliver a quick-sealing solution.

The available standard cross sections are: 0.040”, 0.062”, 0.070”, 0.103”, 0.139”, 0.210”, 0.275”, 0.312”, 0.375”, 0.500”

If some of your applications may require tighter Cross-Section Tolerances, East Coast Shielding can provide whatever your re-quirements may be.

Advantages of Spliced O-Rings:

- O-rings or Seals can be made from a range of compounds (ECS3 Series Conductive Silicone & ECS300 Series Non-Conductive Silicone)

- No Tooling required for standard ID/OD O-Rings Cord

- O-rings can be made in virtually any diameter and length

- Shorter lead times and faster delivery than molded rings

O-Ring Cord Cut Length Calculator:

Calculated O-ring Cord Cut Length: ((OD+ID)/2) x Pi = length

(Pi = 3.1416), ID = OD—(2 x C/S)

O-Ring Materials

An O-ring is only as good as the material it is crafted from. East Coast Shielding makes certain that we have a huge selection of top quality materials to choose from:

- Silicone (ECS300 Series)

- Fluorosilicone

- Conductive elastomers (ECS3 Series)

- Silicone sponge elastomers (ECS300 Series)

Our massive selection of materials guarantees that we can make an O-ring that is right for you no matter what the application. Please ask us about custom material.

M83528/002 - M83528/005 - M83528/013

| Part # | C.S. | I.D. | M83528/002 | M83528/005 | M83528/013 |

| ECS3-200-XXXX | .030 | .442 | 005/001 | ||

| ECS3-201-XXXX | .030 | .577 | 005/002 | ||

| ECS3-202-XXXX | .030 | .692 | 005/003 | ||

| ECS3-203-XXXX | .030 | .817 | 005/004 | ||

| ECS3-204-XXXX | .039 | .425 | 005/005 | ||

| ECS3-205-XXXX | .048 | .295 | 005/006 | ||

| ECS3-206-XXXX | .050 | .533 | 005/007 | ||

| ECS3-207-XXXX | 005/008 | ||||

| ECS3-208-XXXX | 005/009 | ||||

| ECS3-209-XXXX | 005/010 | ||||

ECS3-210-XXXX |

005/011 | ||||

ECS3-211-XXXX |

005/012 | ||||

| ECS3-212-XXXX | 005/013 | ||||

| ECS3-213-XXXX | 005/014 | ||||

ECS3-214-XXXX |

.070 | .145 | 002/007 | ||

| ECS3-215-XXXX | .070 | .301 | 002/011 | ||

| ECS3-216-XXXX | .070 | .364 | 002/012 | ||

ECS3-217-XXXX |

.070 | .426 | 002/013 | ||

ECS3-218-XXXX |

.070 | .489 | 002/014 | ||

| ECS3-219-XXXX | .070 | .495 | 005/015 | ||

ECS3-220-XXXX |

.070 | .551 | 002/015 | ||

ECS3-221-XXXX |

.070 | .610 | 005/016 | ||

| ECS3-222-XXXX | .070 | .635 | 005/017 | ||

| ECS3-223-XXXX | .070 | .667 | 005/018 | ||

| ECS3-224-XXXX | .070 | .676 | 002/017 | ||

| ECS3-225-XXXX | .070 | .739 | 002/018 | ||

| ECS3-226-XXXX | .070 | .801 | 002/019 | ||

| ECS3-227-XXXX | .070 | .860 | 005/019 | ||

| ECS3-228-XXXX | .070 | .864 | 002/020 | ||

| ECS3-229-XXXX | .070 | .926 | 002/021 | ||

| ECS3-230-XXXX | .070 | .989 | 002/022 | ||

| ECS3-231-XXXX | .070 | 1.114 | 002/024 | ||

| ECS3-232-XXXX | .070 | 1.176 | 002/025 | ||

| ECS3-233-XXXX | .070 | 1.230 | 005/020 | ||

| ECS3-234-XXXX | .070 | 1.239 | 002/026 | ||

| ECS3-235-XXXX | .070 | 1.364 | 002/028 | ||

| ECS3-236-XXXX | .070 | 1.614 | 002/030 | ||

| ECS3-237-XXXX | .070 | 1.864 | 002/032 | ||

| ECS3-238-XXXX | .070 | 3.489 | 002/043 | ||

| ECS3-239-XXXX | .103 | .612 | 002/114 | ||

| ECS3-240-XXXX | .103 | .676 | 002/115 | ||

| ECS3-241-XXXX | .103 | .799 | 002/117 | ||

| ECS3-242-XXXX | .103 | 1.362 | 002/126 | ||

| ECS3-243-XXXX | .103 | 1.487 | 002/128 | ||

| ECS3-244-XXXX | .103 | 1.612 | 005/022 | ||

| ECS3-245-XXXX | .103 | 1.737 | 002/132 | ||

| ECS3-246-XXXX | .103 | 1.790 | 005/023 | ||

| ECS3-247-XXXX | .103 | 1.862 | 002/134 | ||

| ECS3-248-XXXX | .103 | 2.362 | 002/142 | ||

| ECS3-249-XXXX | .103 | 2.550 | 002/145 | ||

| ECS3-250-XXXX | .103 | 3.987 | 002/155 | ||

| ECS3-251-XXXX | .115 | 2.683 | 013/029 | ||

| ECS3-252-XXXX | .139 | 2.011 | 013/022 |

* Material table below *

| Carbon 1000 | Nickel Graphite 2000 | Nickel Graphite 2000F | Silver Aluminum 5000 | Silver Aluminum 5000F | Silver Glass 6000 | Silver Copper 8000 | |

| - | - | - | Type B | Type D | Type M | Type A & K | |

| Elastomer | Silicone | Silicone | Fluoro- silicone | Silicone | Fluoro- silicone | Silicone | Silicone |

| Color | Black | Dark Gray | Dark Gray | Blue* | Blue* | Tan | Tan |

| Specific Gravity, gm/cc | 1.2 | 1.95 | 1.95 | 2.0 | 2.0 | 1.9 | 3.5 |

| Durometer Shore A | 70 | 30-70 | 65 | 65 | 70 | 65 | 65 |

| Volume Resistivity, Ohm-cm | 7.0 | 0.10 | 0.10 | 0.008 | 0.012 | 0.006 | 0.004 |

| Operating Temperature: Min C | -55° | -55° | -55° | -55° | -55° | -55° | -55° |

| Operating Temperature: Max C | 200° | 150° | 150° | 160° | 160° | 160° | 125° |

| Compression Deflection % Min. | 3.5 | 3.5 | 3.0 | 3.5 | 3.5 | 3.5 | 3.5 |

| Tensile Strength, P.S.I. | 650 | 150 | 150 | 200 | 180 | 200 | 200 |

| Elongation % Min. | 100% | 100% | 100% | 100% | 60% | 100% | 100% |

| Elongation % Max. | - | - | - | 300% | 260% | 300% | 300% |

| Compression Set % | 40 | 35 | 25 | 32 | 30 | 30 | 32 |

| Tear Strength lb./in. | 40 | 40 | 35 | 30 | 35 | 30 | 25 |

| Shielding Effectiveness (100 Mhz) | 80 | 100 | 100 | 120 | 120 | 100 | 120 |

| Shielding Effectiveness (500 Mhz) | 80 | 100 | 100 | 120 | 120 | 100 | 120 |

| Shielding Effectiveness (2 Ghz) | 60 | 100 | 100 | 115 | 115 | 90 | 120 |

| Shielding Effectiveness (10 Ghz) | 50 | 100 | 100 | 115 | 115 | 90 | 120 |